APR Intercooler Discussion – Looks can be Deceiving

In 2006, APR began development of the APR Front Mount Intercooler System for VW’s 2.0T engine. This came after being commissioned by Volkswagen of America to create the ultimate performance hardware for their R-GTI Concept car. A North American Nation Wide Tuner Challenge was held by VW and participation was extended to APR and other tuners in the industry. The results, which were overseen by the SCCA and several automotive magazine editors and journalists, proved APR powered vehicles set the bar by a large margin in all performance categories and the APR prototype intercooler and Stage III turbo system were made available to the public.

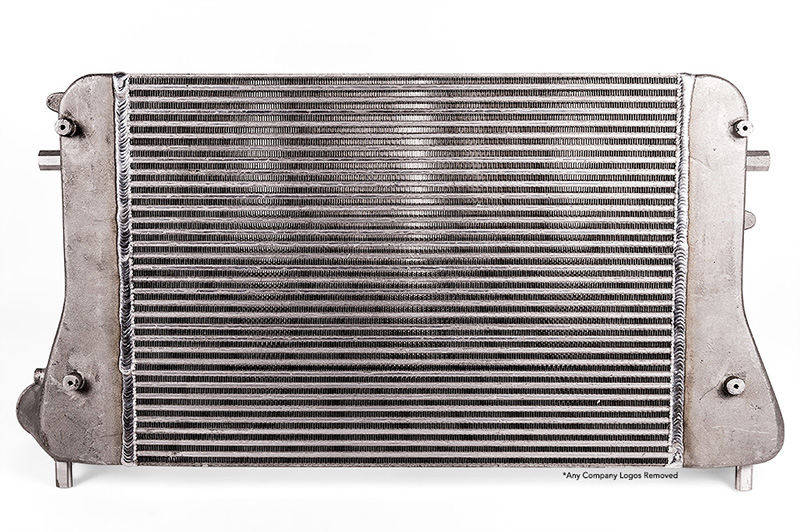

In recent years, many intercoolers similar in appearance have entered the market. This came shortly after several overseas companies began copying designs and selling them for pennies on the dollar with any company’s name on the hoses and end tanks. Many of these items can be found online using APR’s own product photography, but the actual product is a far cry from the original in almost every way, shape and form.

This page shows the differences between APR’s intercooler in terms of performance, quality, fitment, support and more vs one that look similar. This will not only help consumers to spot a fake being passed off as an APR intercooler, but also see the quality and fitment differences of the APR's Intercooler and the competition’s intercooler. Our testing data will further illustrate the impact on performance, which proves looks can be deceiving.

Intercooler Performance Testing:

To measure the performance difference between two intercooler cores, APR conducted back-to-back testing, on the same day in order to control data as tightly as possible. The test vehicle was fitted to APR’s dyno with the room’s exhaust and coolant fans set to a controlled value. Six dyno tests were conducted while data logging various engine variables in real-time using APR’s ECU Explorer software. Data not available from the vehicle’s ECU, such as the pre-intercooler boost and temperature, were collected with extra sensors installed before the intercooler’s inlet.

Starting Conditions (APR Intercooler vs "Similar Looking" Intercooler):

- Ambient Temp: 84.9 °F vs 81.1 °F

- Ambient Baro: 29.3 in-HG vs 29.3 in-HG

- Ambient Humidity: 36% vs 35.3%

- IAT in the Intake Manifold: 94.1 °F vs 86 °F

Starting conditions were nearly as identical as possible. However, the “Similar Looking” Intercooler core tests were conducted in more ideal conditions with an intake air temperature 8.1 degrees less. Ambient temperature was also 3.8 degrees cooler.

Testing Information:

- Dyno Run Length: 12 seconds

- Time Between Runs: 5 seconds

- Number of Runs: 6

- APR Testing Time: 3:38:47 PM

- Competitor Testing Time: 5:18:09 PM

The APR Intercooler was tested first. Upon completion of the tests, the vehicle was removed from the dyno and taken to the workshop. The APR Intercooler was removed and the competitor’s intercooler was installed. Finally the car was reconnected to the dyno and testing continued.

Results:

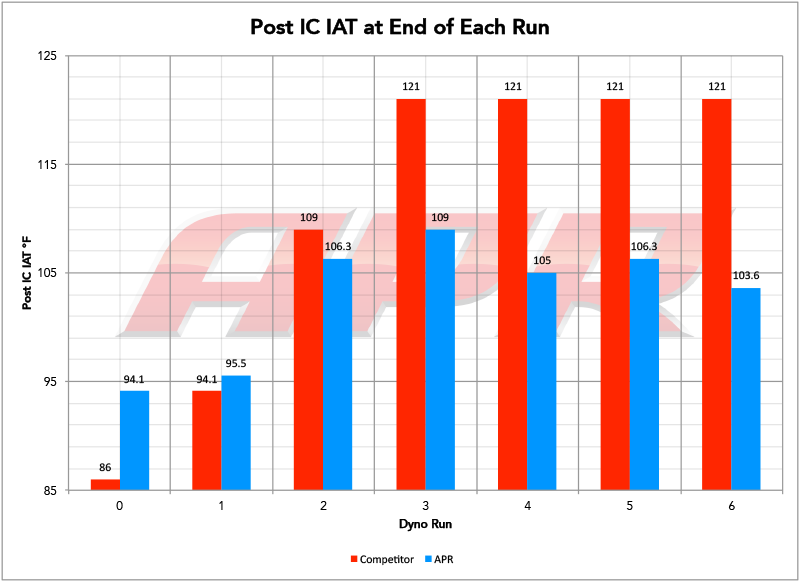

The APR intercooler core preformed dramatically better than the cheaper alternative.

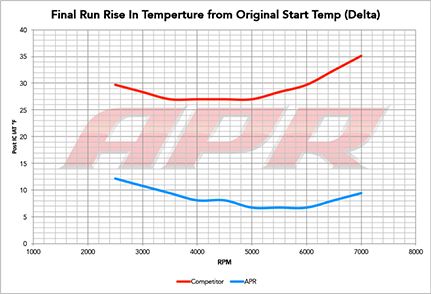

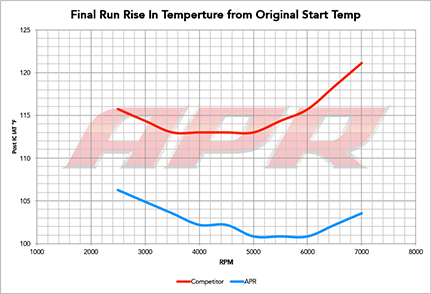

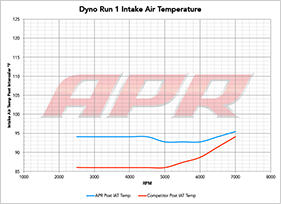

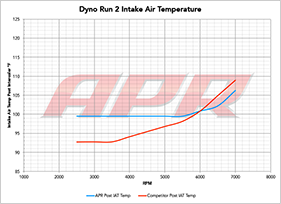

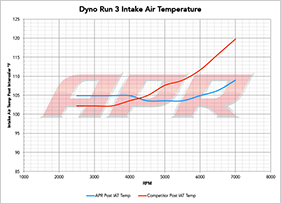

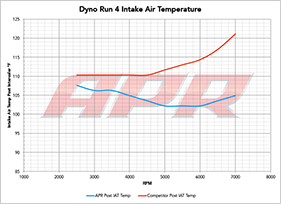

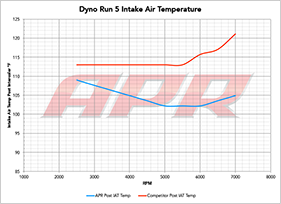

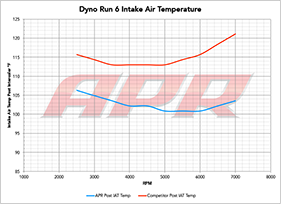

By 7,000 RPM, on each of the six runs, intake air temperature was no greater than 6 °F from the starting IAT of each run and during three runs were actually 4.05 °F LESS than the starting temperature of each run. The competitor’s core didn’t fair so well, seeing as high as a 17.55 °F increase in intake air temperature from start to end on a single pull. See graphs posted below for IAT during each pull.

By the sixth back-to-back run the APR Intercooler had no problem reducing post IC intake air temperature at 7,000 RPM. Temperature dropped from as high as 330.4 °F down to 103.55 °F. However, the cheaper alternative struggled to reduce intake air temperature below 120 °F by the third dyno run, despite better starting and ambient conditions.

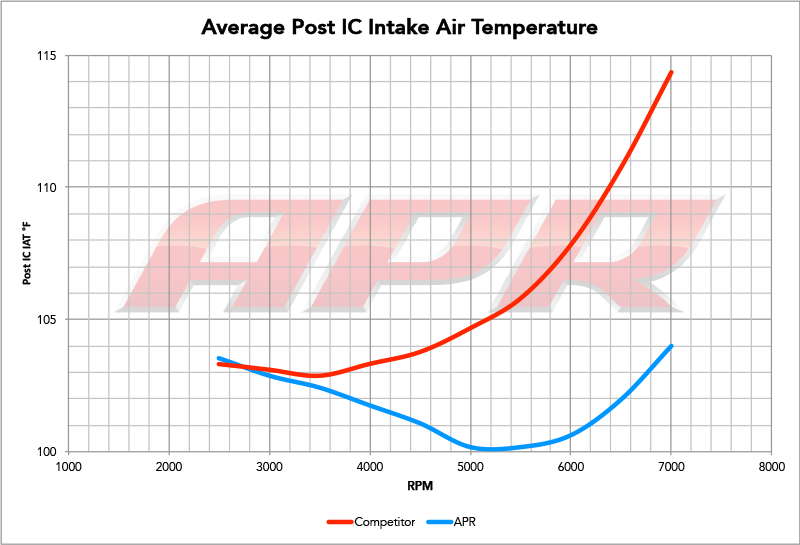

A six run average showed the APR Intercooler starting with IAT’s at 103.55 °F, which dipped as low as 100.175 °F around 5,000 RPM, with a final temp of 104 °F by 7,000 RPM. The competitor’s intercooler showed a six run average starting IAT of 103.33 °F which rapidly increased to 114.35 °F.

The graphs below show the post-IC intake air temperature for the APR intercooler and the competitor’s intercooler from each dyno pull.

Manufacturing, Material and other Specifications:

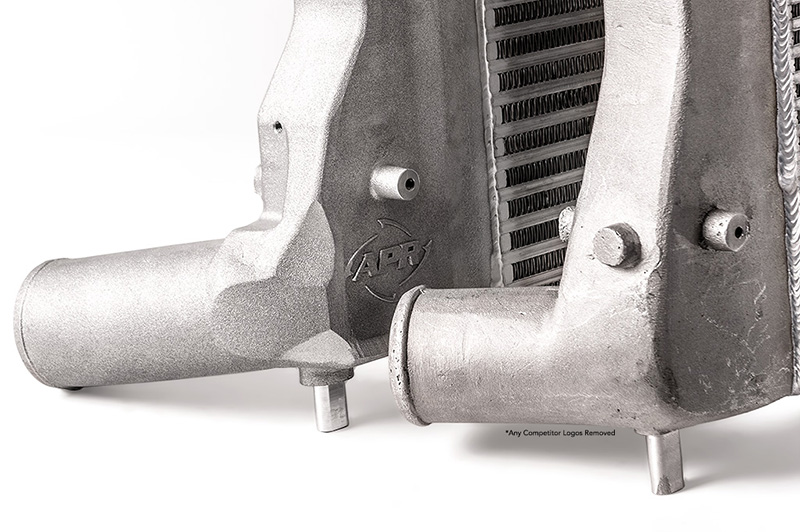

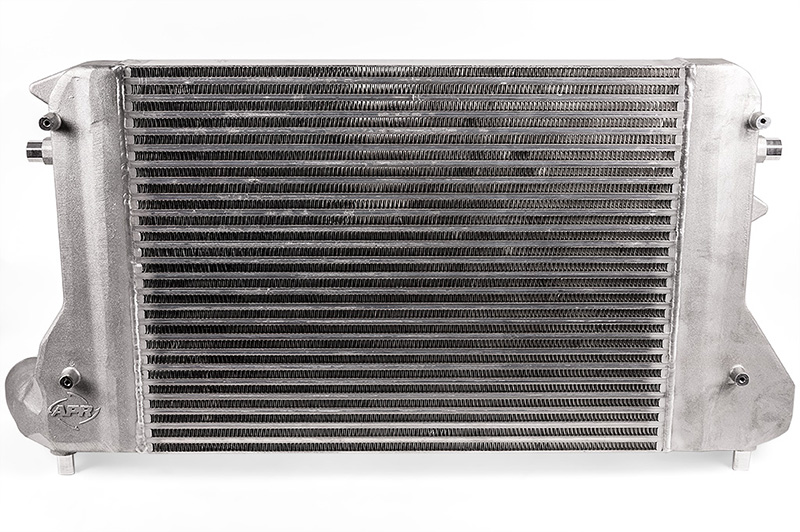

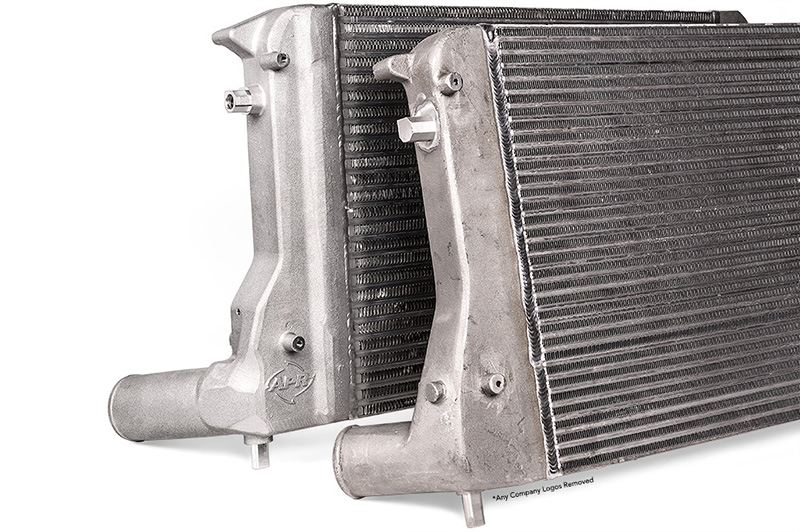

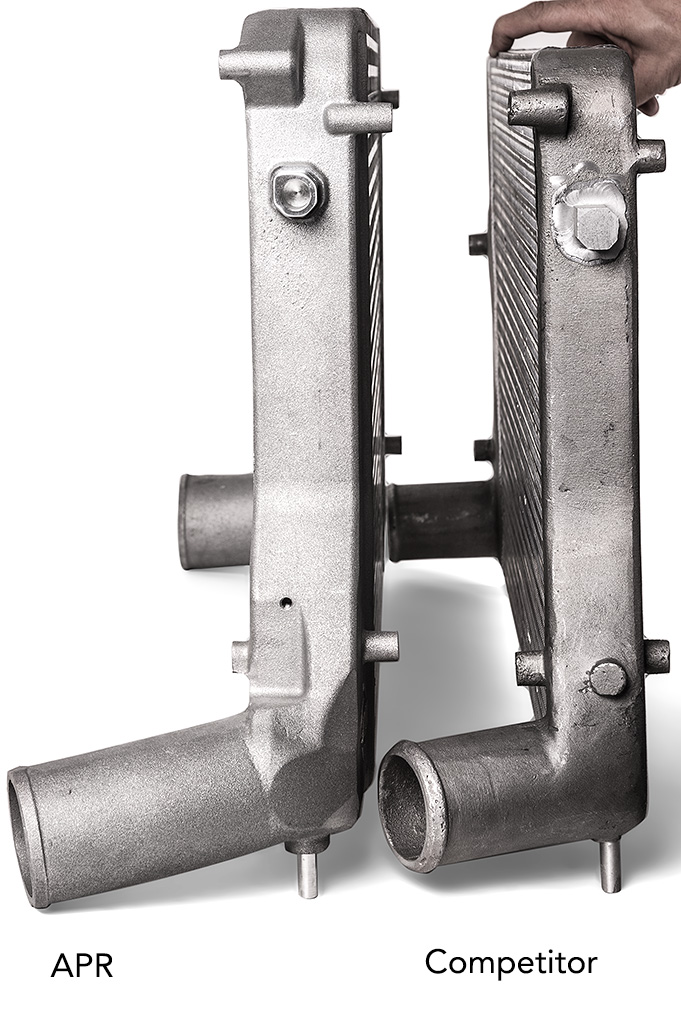

The all aluminum investment cast end tanks of the APR Intercooler are cast using high quality vendors to ensure a repeatable design, high tolerances and direct access to our casting partners should an issue ever arise. The raw end tanks are each machined in house at APR. The inlet and outlet pipes on the APR intercooler are much larger than stock and larger than our competition's.

The long and smooth neck on the inlet and outlet allow for a clean mounting surface to avoid boost leaks.

APR machines unnecessary aluminum from the side mounting points to lower the intercoolers weight as much as possible. The end tank castings were designed not only for fitment and airflow, but also weight savings. This is why the APR intercooler’s end tanks are sharp and geometric compared to the rounded generic design of the competition’s intercooler. The APR Intercooler is around 5 LBS lighter than the competition’s.

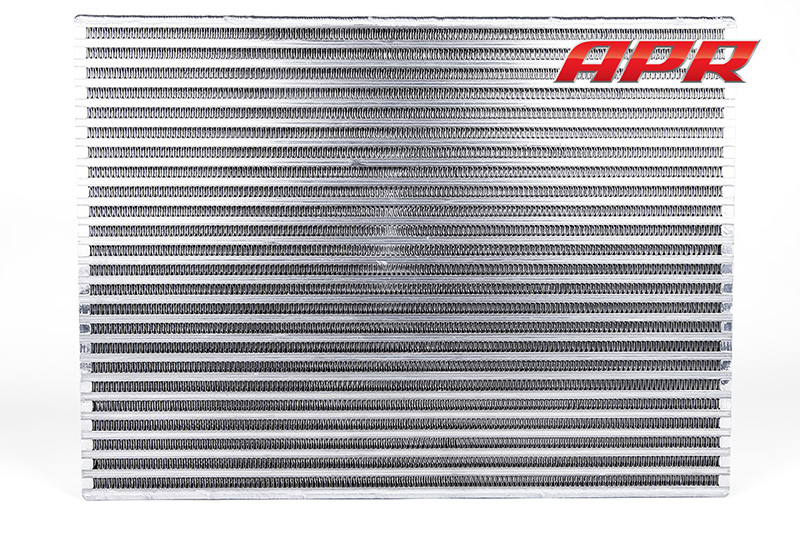

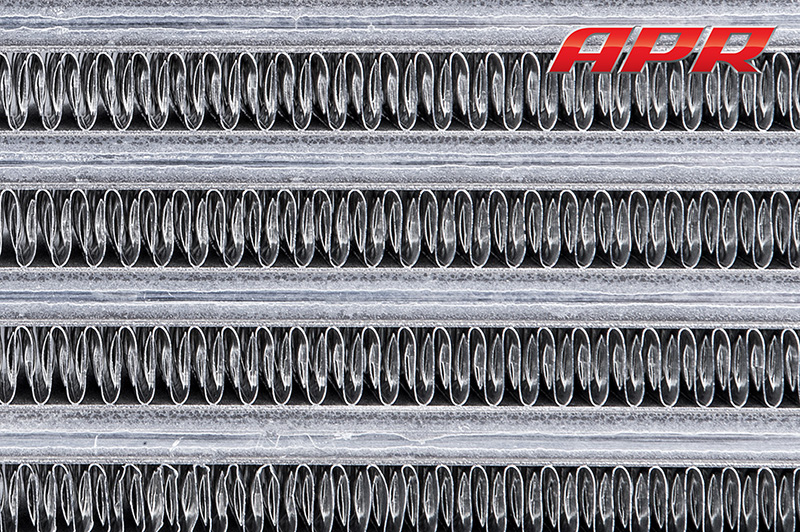

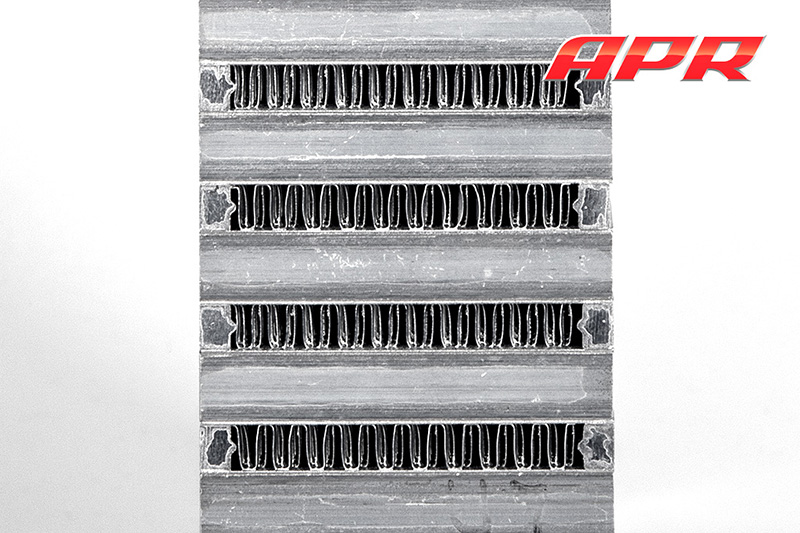

The APR intercooler core is manufactured to APR’s exact specifications. In this application a staggered and louvered fin design is the best choice, which is backed up by our internal testing of several core designs. When selecting core fin density, pressure drop must be considered. Increasing density will result in more pressure drop across the core, which means the turbo will work hard to create the same pressure in the manifold compared to a freer flowing core.

Through testing of several different densities, APR found a balance between cooling and pressure drop to achieve the best possible results. A dense core was most beneficial in this application due to the intercooler core’s dimensions as well as the end tank design. Through CFD analysis, APR’s engineers designed end tanks which promote use of the entire intercooler core, rather than the first few rows. This was further backed by the density of the core, which promotes filling of the entire end tank plenum for even charge air distribution. Intercooler width was carefully selected to maximize surface area without disrupting end tank design as a wider core design showed less even distribution of charge air across the upper portion of the intercooler.

The APR intercooler core is 16.25” tall, 2.25” thick and 23.2” wide.

Core Thickness Comparison

APR Intercooler Core Overview

APR Intercooler Core Ambient Air Path

Competitor Core Front Ambient Air Path

APR Intercooler Core Charge Air Path

Small manufacturing anomalies and defects in the massive intercooler core’s surface can lead to small boost leaks which left untested are extremely difficult to locate. APR guarantees leak proof operation, as each assembled unit is pressure tested to 30 PSI.

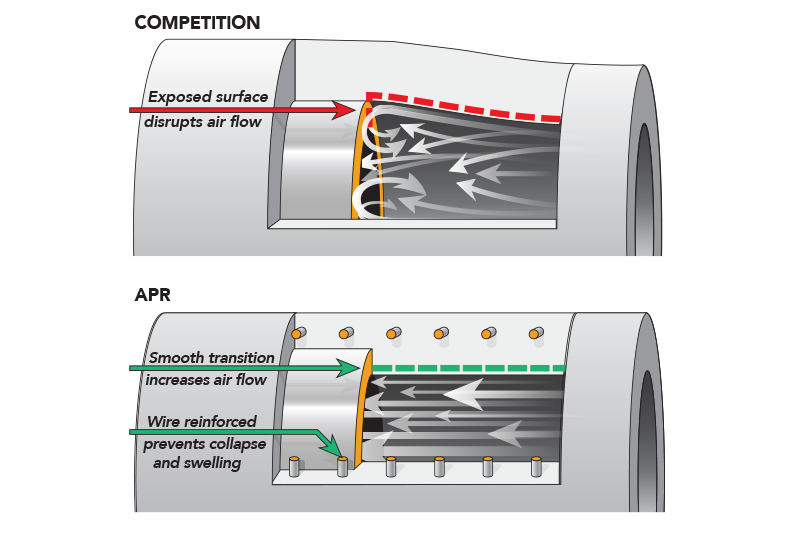

The specific design of the APR intercooler hoses allows for smooth airflow into and out of the intercooler. The multi-ply hose material will not swell under boost and the stepped APR Easy-Flow Silicone hose design allows for a smooth airflow transition from one pipe to the other. The competition’s hoses typically do not feature this design addition, resulting in turbulent airflow as seen below.

Casting Quality:

Words cannot describe the absolutely tremendous difference in quality between the castings of the APR Intercooler and the competition’s. Every edge and surface of the APR intercooler is razor sharp and free of defects while the competition’s is riddled with casting flaws, loose tolerances, voids, extra casting pieces ready to fall off and enter your engine at a moment’s notice and other strange casting attributes associated only with the worst practices in the industry. Expect the inside of an APR intercooler end tank to be smooth and specific for routing intake air while our competition’s are littered with extra mounting knobs protruding into the design which disrupts smooth airflow.

Competitor Core End Tank Casting Issues

Poor casting quality extends beyond just looks. It impacts all of the following:

- Performance – Airflow through end tanks

- Fitment – Poor tolerances

- Weight – Extra unnecessary casting attributes

- Leaks – Casting voids are prone to leaking

- Engine Safety – Casting flack can easily break free and enter your engine

Competitors have attempted to hide these defects from customers through painting, powder coating, sanding and polishing end tanks, but this only superficially mask the issues.

Fitment:

The APR Intercooler fits perfectly. The competition’s is not even close. The following areas are known issues with the competition’s intercooler:

- Every mounting point

- Every screw hole

The competition’s intercooler will loosely fit into each mounting point while other factory components must be bent to line up with the screw holes. In some cases, the screw holes are so far off or filled with excess casting material, they have to be retapped before they can be installed increasing labor costs and reducing the shop’s profitability which will have to be made up in other areas.

All mounting points and screw holes on the APR intercooler are in the correct location. They are machined in house to ensure proper sizing and proper thread pitch.

With very little communication or factual exchange of information between our competitor’s and their overseas suppliers, fitment issues will pop up all the time. There’s no fixing the issue either as the competitors don’t own the tooling used to cast each piece. They are simply purchasing parts from random vendors, many of whom have actually copied bad design, further pushing tolerances out of spec. Depending on the factory pumping out the parts, it will either fit one way or another way.

Support:

Included with every APR Intercooler System is a printed and spiral-bound instruction manual covering each step of the detailed install. Most competitors include no directions at all. If you ever run into a problem, you can simply call APR for support as we currently staff more employees who have installed an APR Intercooler than many companies employ in their entire company.

The APR Intercooler also comes with a lifetime warranty which is an important aspect often not discussed. Many companies have the ability to offer “lifetime warranties” but many of these companies do not stay in business for long periods of time. Once they’re out of business, you’ll have no way to get a replacement part should you ever need one. It’s not uncommon to hear of a customer getting into an accident and in the process ripping a hose or damaging some other component. In those cases, we can quickly and easily ship the customer a new hose to aid in the repair but for the companies out of business or the ones purchased through cheap EBay outlets, there are no replacement parts when the need arises.

Finally, if the install is not for you, no worries! APR’s vast dealer network makes installation at a local shop easy. For those who don’t have an APR shop in town, our included instruction manual makes the process a walk in the park, saving you money spent on unnecessary labor.

Power:

A performance intercooler system needs to dramatically lower intake air temperature to a level that’s acceptable for creating safe and reliable power. It needs to continue doing over a long period of time without "heat soaking." Heat soak is when an intercooler becomes so hot it’s unable to cool the intake air effectively.

There will be many who will look past casting quality, fitment flaws, lack of support and so on simply to save a few dollars and many may be under the impression the data we’ve shared above does not translate to any real world differences in power.

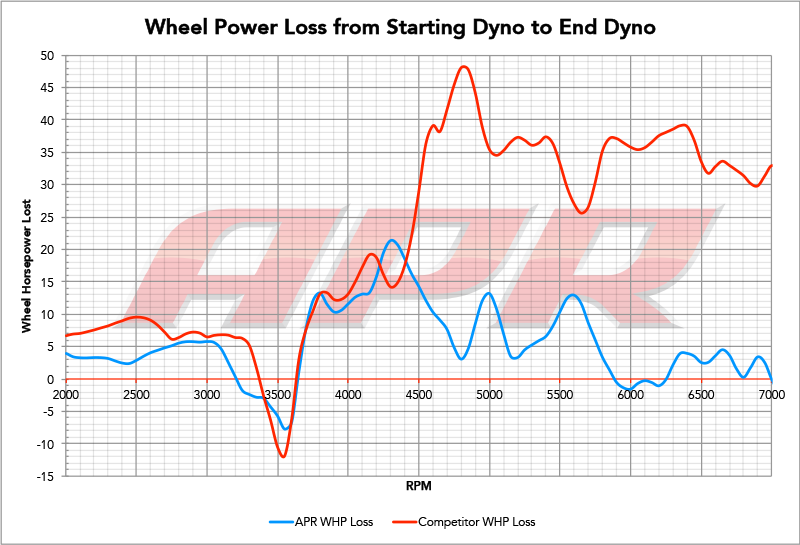

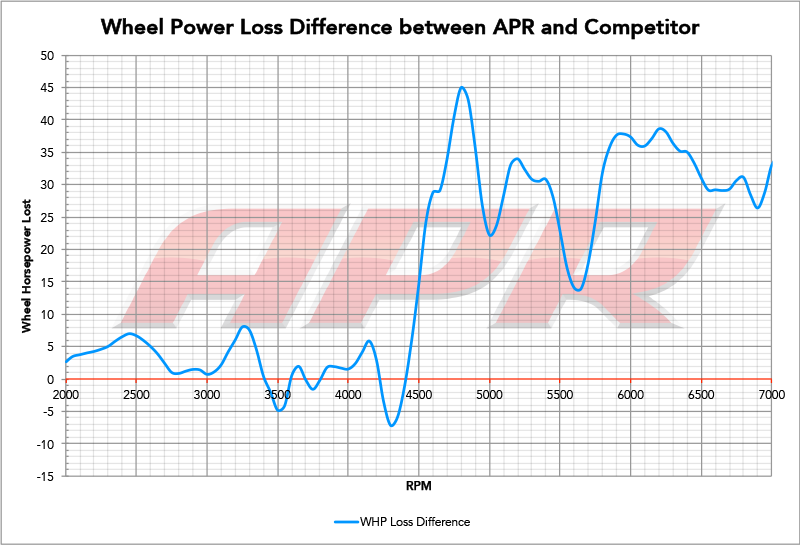

During our testing on the dyno, we were able to prove without a shadow of a doubt that the performance differences are massive. As mentioned above in the testing notes, each intercooler was tested back to back without a cool down period to measure temperature changes, vehicle operating variables and most importantly, power loss. Analyzing the average power losses after the turbocharger spooled showed an incredibly small 6.8 WHP loss across the power band with the APR intercooler system. However the other core lost an average of 30.1 WHP across the power band.

On average, the APR intercooler was able to retain 23.3 WHP over the cheaper alternative which throws it into the same league as a major upgrade even though it’s being compared to what many would already consider an “upgrade.”

This industry is filled with many trick and gimmicks but you will not find this when you purchase APR products. This is why you often hear the bitterness of poor quality is remembered long after the sweetness of a low price is forgotten.