APR HIGH PRESSURE FUEL PUMP - HITACHI - 2.9T AND 3.0T EA839

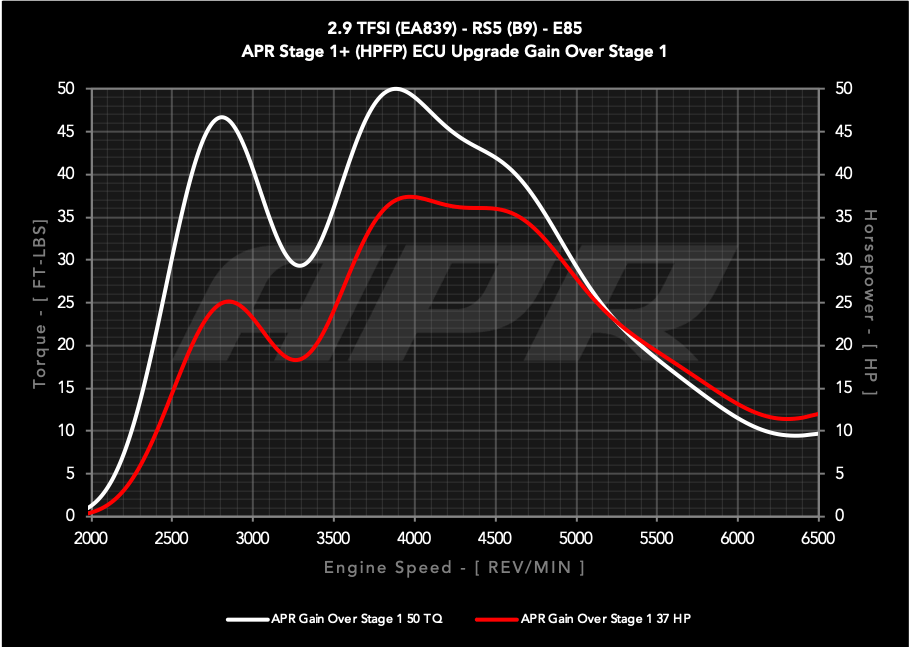

The APR High Pressure Fuel Pump (HPFP) increases maximum volume of fuel the HPFP can deliver by 37% over stock! In doing so, the direct injection fueling system is capable of satisfying fueling requirements set forth by high horsepower setups. This is accomplished by increasing the displacement of the pump using high quality components to exacting tolerances. On the B9 2.9T we achieved an additional 37 AWHP and 50 AWFTLBS over our Stage 1 (E85) ECU Upgrade by adding the pump and running our Stage 1+ (E85) ECU Upgrade!

The APR High Pressure Fuel Pump (HPFP) increases maximum volume of fuel the HPFP can deliver by 37% over stock! In doing so, the direct injection fueling system is capable of satisfying fueling requirements set forth by high horsepower setups. This is accomplished by increasing the displacement of the pump using high quality components to exacting tolerances. On the B9 2.9T we achieved an additional 37 AWHP and 50 AWFTLBS over our Stage 1 (E85) ECU Upgrade by adding the pump and running our Stage 1+ (E85) ECU Upgrade!

Features and benefits

- Delivers up to 519-551 HP with 360-377 FT-LBS depending on octane

- Dramatically increases the volume of fuel displaced by the HPFP by 37%

- +37 AWHP / +50 AWFTLS (B9 2.9T E85 Stage 1 vs 1+ with HPFP)

- Maintains higher pressures under demanding situations

- Ideal for high output race cars and track use

- Fully rebuilt in house

- Fully machine tested and broken in before shipping

- Includes a new OEM pump (MS100207)

- Rebuild of your existing pump (MS100211)

- Upgraded and weight matched spring

- Titanium retainer

- DLC coated piston

- Heat-treated bearing-grade stainless steel material

- .00004" dimensional tolerances

- .00005" geometrical tolerances

Why APR?

High quality components and extreme tolerances:

The HPFP internals must be machined to extreme tolerances and installed in a clean environment or the pump can easily fail. Dimensional tolerances on the APR HPFP are as tight as .00004” and geometric tolerances are as tight as .00005”. The plunger and barrel are created from certified and heat-treated bearing-grade stainless steel and the plunger undergoes a special diamond like coating process for exceptional surfaces hardness and ultra-reliable operation. To prevent float associated with altering the plunger’s mass, APR supplies each unit with a properly specified spring. All necessary internal seals are replaced.

Internal testing:

All APR HPFPs are assembled in house under strict assembly guidelines. Each pump is then tested on our test rig to ensure the pumps operate as designed. This step is important for several reasons. It’s critical in determining if a pump has a failure from incorrect install, a leaking seal, or a bad solenoid. Secondly, a seized pump on the vehicle at startup can cause damage to the engine’s camshaft. By testing each pump, we all but eliminate these possibility.

Proven track record:

APR pioneered HPFP upgrades in the early days of VAG direct injection engines. Soon after, APR became an OEM supplier of HPFP and GDI components to VAG for use in various race cars, racing series, project cars, and concept vehicles. The APR HPFP has been at the center of countless motorsport victories across the globe and has operated with a nearly perfect tract record since the program’s motorsport backed inception in 2006. With tens of thousands of pumps sold, APR has a wealth of knowledge, and manufacturing expertise necessary to deliver a product that will and has stood the test of time.

| Product | Part Number | Price Exc. VAT | Price Inc. VAT | |

|---|---|---|---|---|

| High pressure fuel pump | MS100207 | £1166.31 | £1399.57 |